The sea is wide and the spring tide is rising. It is the right time to set sail -- Weihai news in-depth reports on Weihai Ziguang intelligent factory

On June 26, Weihai news visited and investigated Weihai Ziguang intelligent factory, experienced the results of the transformation between the old and new kinetic energy of the enterprise, felt the surging development momentum of the intelligent factory, and enjoyed a bright future in the new era, and made in-depth reports:

For the high-quality development of the wave economy, we should vigorously improve the industrial development level and promote the high-end, intelligent and green development of the industry. As a traditional industry, factory digital transformation and intelligent production are the inevitable trend of the development of the times.

Weihai Ziguang Biotechnology Development Co., Ltd. put more than 20 automatic production lines into operation last year, and another 20 intelligent production lines were launched this year. The intelligent production of the whole production line and the whole process has also increased the productivity and production efficiency of the enterprise by four times.

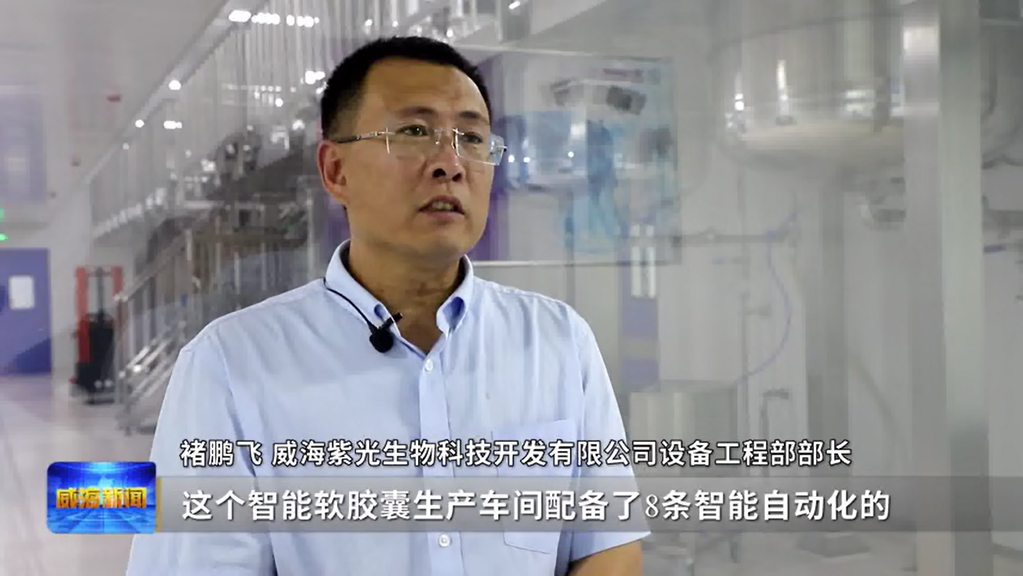

Entering the intelligent soft capsule production workshop of Weihai Ziguang, clean, efficient and intelligent operation is the best summary here.

Chu Pengfei, director of equipment Engineering Department of Weihai Ziguang Biotechnology Development Co., Ltd., introduced that the intelligent soft capsule production workshop is equipped with 8 intelligent and automatic glue dispensing and solution production lines, 10 fully automatic soft capsule pressing, shaping and intelligent drying lines, with a daily output of more than 20million capsules, 1 fully automatic dropping pill production line, with a daily output of more than 2million capsules, and 1 fully automatic soft candy production line, with a daily output of more than 10 tons.

The production capacity of the front section is strong, and the packaging efficiency of the rear section is high. From molding to quality inspection and packaging of soft capsules, fully automated operation has been gradually realized. In particular, the six automatic and intelligent bottle CCD visual inspection grain production lines newly launched by Ziguang can produce more than 400000 bottles per day.

What supports the huge production capacity is the diversity and cutting-edge of Ziguang products. In addition to soft capsules, Ziguang is also effective in powder and solid racing. Behind these products, there is a high-level R&D technology team with a master degree accounting for more than 80%. Since the establishment of Shandong Post Doctoral innovation base in 2021, two doctors have been stationed.

Zhanglinlin, the R&D director of Weihai Ziguang Biotechnology Development Co., Ltd., introduced that everyone should give full play to their respective advantages, make use of the technical and theoretical advantages of colleges and universities and combine them with the market, so as to achieve 1+1>2, and transform the technical research in Colleges and universities through enterprises.

With the subdivision track as the framework, the digital intelligence transformation as the engine, and the scientific and technological talents as the fuel, Weihai Ziguang has carried out the automation, digitization and intelligent upgrading iteration of the enterprise, and constantly shaped the core competitive advantage of the industry.

Wangxiaoxue of the product promotion center of Weihai Ziguang Biotechnology Development Co., Ltd. said that after more than 20 production lines were put into operation last year, another 20 intelligent production lines were put into operation this year, and the capacity and production efficiency were increased by four times. Weihai Ziguang will take this iteration and upgrade as a new starting point for development, and double its output value in 3 to 4 years.

Source: Weihai news

Scan code and follow us

Grow together with purple light

Previous:[Qilu Evening News] social responsibility+feelings of people's livelihood, Weihai Ziguang Group donated more than 2.4 million yuan in total